Emerging technologies turn real-time data into visual, interactive workflows that make complex systems understandable at a glance. Moreover, teams gain a shared single source of truth they can explore together in 3D, so decisions are faster, training is safer, and customer experiences feel more personal and engaging.

Why this convergence now

Firstly, IoT maturity means telemetry is reliable, abundant, and timely enough to keep virtual models “alive.” Secondly, AR/VR hardware and software have become practical for daily use, therefore enabling realistic walk-throughs, collaborative design reviews, and high-fidelity training without disrupting live operations.

What these technologies are

Emerging technologies enable a digital twin as a living virtual counterpart of an asset, process, or system, continuously refreshed with real data to monitor, simulate, and optimize performance. Additionally, IoT delivers the sensors, gateways, and networks that keep the twin up to date. Likewise, AR/VR and the metaverse create immersive 3D spaces where teams explore the twin at human scale and collaborate live.

How integration works

To clarify, sensors stream data into a twin platform that models structure, state, and behavior. Then, AR/VR clients render that twin in an immersive environment where teams annotate issues, rehearse procedures, and run what‑if scenarios—before making any physical change.

Core enterprise use cases

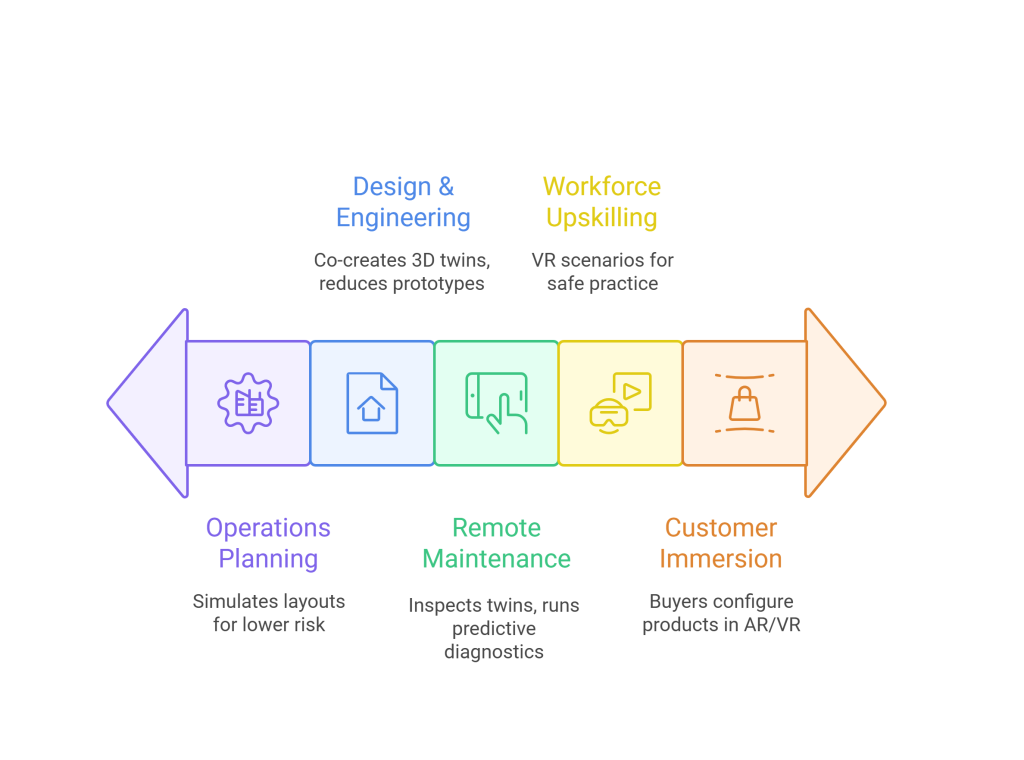

- Workforce upskilling: VR scenarios tied to real failure modes help new hires practice safely, thereby reducing errors and speeding time‑to‑competency.

- Remote maintenance: Technicians inspect twins, check health indicators, and run predictive diagnostics to cut unplanned downtime.

- Design and engineering: Cross‑functional teams co‑create around 3D twins, reduce physical prototypes, and compress design cycles.

- Customer immersion: Buyers configure products in AR/VR, test options virtually, and make confident decisions with fewer returns.

- Operations planning: Leaders simulate layouts, throughput, and disruptions to guide capital and staffing with lower risk.

Business value in plain terms

Consequently, teams fix problems in the twin before they appear on the floor, which lowers costs and raises first‑pass success. Furthermore, training becomes measurable and repeatable, while customer journeys become more interactive, personalized, and conversion‑friendly.

Technical building blocks

- Data and models: Stream telemetry into a twin graph that captures components, relationships, constraints, and state over time.

- Intelligence and simulation: Use rules, physics, and machine learning to predict failures, optimize parameters, and compare scenarios.

- Immersive front ends: Deliver multi-user AR/VR sessions with avatars, live overlays, and shared tools for joint decision‑making.

- Governance and lifecycle: Enforce identity, access, lineage, and safety standards so twins remain accurate, secure, and auditable.

Implementation roadmap

Firstly, choose one high‑value use case with clear KPIs—such as reducing downtime, improving training throughput, or shortening design cycles. Secondly, instrument priority assets, build a clean ingestion pipeline, and select a twin platform that connects to analytics and AR/VR tools. Then, measure outcomes early and iterate quickly.

Phased adoption approach

To begin with, pilot a single line, site, or procedure and validate model fidelity against real results. Next, integrate with ERP/PLM/CMMS to close feedback loops and scale across adjacent processes. Finally, expand to customer-facing experiences and partner collaboration hubs to maximize ROI.

Design patterns and best practices

- Right‑sized detail: Model what is needed for decisions; avoid modeling every bolt if it adds cost without impact.

- Signal strategy: Stream safety‑critical signals in real time and batch non‑critical telemetry to manage costs.

- Role‑first UX: Give operators guided steps, designers parametric controls, and executives KPI overlays in context.

- Secure by default: Apply least privilege, segment networks, encrypt sensitive streams, and log immersive sessions.

Metrics that matter

In practice, track time‑to‑competency, mean time to repair, unplanned downtime, first‑pass yield, and dwell time in immersive demos. Moreover, monitor simulation accuracy, decision lead time, and session participation to sustain momentum and justify scaling.

Industry snapshots

- Manufacturing: “Metafactory” twins power what‑if planning, remote troubleshooting, and mixed‑reality training that reduce stoppages and defects.

- Automotive: Vehicle twins accelerate validation, ergonomics checks, and immersive test drives that compress feedback loops.

- Retail: Virtual stores and supply chain twins personalize journeys and anticipate demand shifts earlier.

- Healthcare: Procedure rehearsals and facility flow twins improve preparedness, safety, and throughput.

Challenges and how to mitigate

However, integration complexity and data quality gaps can erode trust in the twin, so standardize schemas, validate at the edge, and automate data quality checks. Additionally, XR adoption hinges on ergonomics and change management; therefore, match devices to tasks, run enablement programs, and support frontline teams. Finally, protect IP with strict access, encryption, and clear collaboration agreements.

Reference architecture

In essence, combine edge gateways and stream processing with a twin modeling layer, add simulation/AI services, and expose the twin to AR/VR and enterprise systems via APIs. Consequently, a policy‑driven identity and observability layer keeps everything secure, governed, and measurable across the lifecycle.

Future trends to watch

Equally, lighter headsets and spatial computing will bring daily immersive collaboration to more roles, not just specialists. Meanwhile, AI copilots will set up simulations, summarize sessions, and recommend next steps, turning twins into proactive decision engines. Likewise, interconnected twins—asset, process, people, and customer—will optimize entire value chains end‑to‑end.

Case study: Production‑line training twin

Firstly, a factory team mirrored a critical assembly line with a digital twin and delivered VR‑based SOP training tied to real fault modes, so technicians practiced high‑risk procedures without danger. Secondly, analytics from simulated faults revealed common missteps, enabling content tweaks and guided workflows that improved adherence. Finally, time‑to‑competency fell, first‑pass maintenance rose, and unplanned downtime dropped as crews transferred virtual skills to live shifts.

Conclusion

Emerging technologies digital twins IoT AR/VR Metaverse unify data, people, and processes in immersive workflows, therefore enabling faster decisions, safer training, and proactive maintenance that lift efficiency, quality, and customer trust across the enterprise.

FAQs

What is an enterprise digital twin?

A live virtual representation of an asset, process, or system that syncs with operations data to monitor, simulate, and optimize performance.

How does the metaverse help?

It provides shared 3D spaces where teams explore twins together, review options, and decide faster with full context.

Which KPIs improve first?

Downtime, MTTR, training throughput, design cycle time, and customer engagement often show early gains.

What slows adoption?

Data quality issues, tool sprawl, headset ergonomics, and governance; address with standards, enablement, and clear ownership.

Where to start?

Pick one high‑value process, set up telemetry, build a minimal twin, connect AR/VR, and prove outcomes within a quarter.